Dongguan Meisheng Intelligent Technology Co., Ltd is specialize in hair tools.

Our company is integrating experienced R&D team, advanced manufacture system, strictly quality control system, professional and responsible sales team, high implementation of after-sales service.

With our keen awareness of the market trend which make our hair tools being hot selling over the world. With the perfect management system, we have the confidence to cooperate with brand customers.

With using the best material, strict detail controlling, high standard requirement to function to manufacture super quality hair tools.

Factory area

Pcs monthly production capacity(hair dryer)

50m Assembly line

Years of industry experience

Patent owner

R&D centers

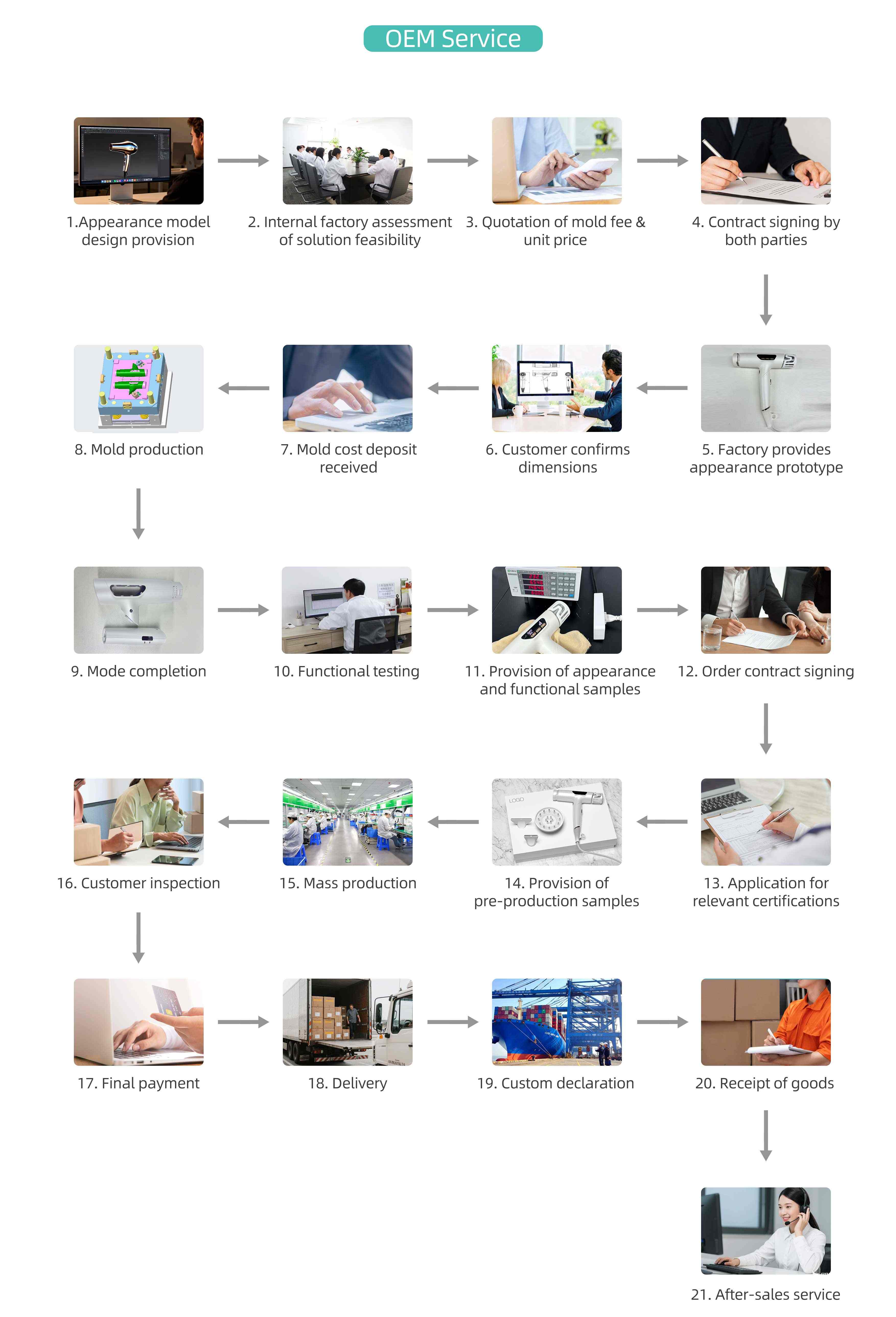

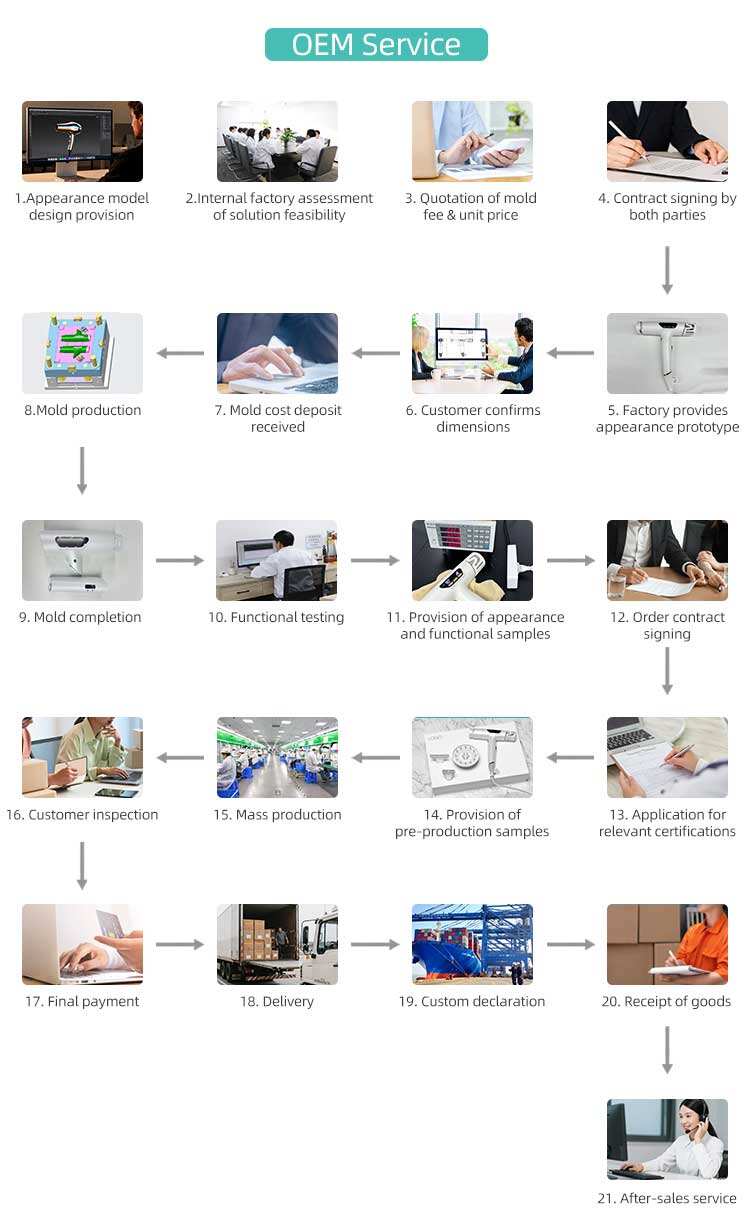

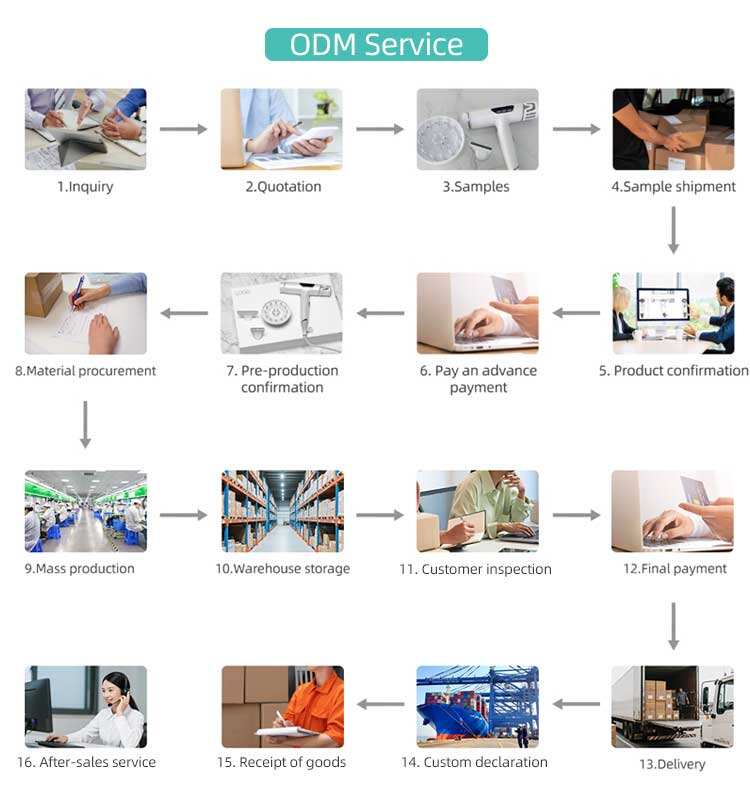

A national high-tech enterprise specializing in the integration of R&D,design and manufacturing, with integrating OEM & ODM capabilities.

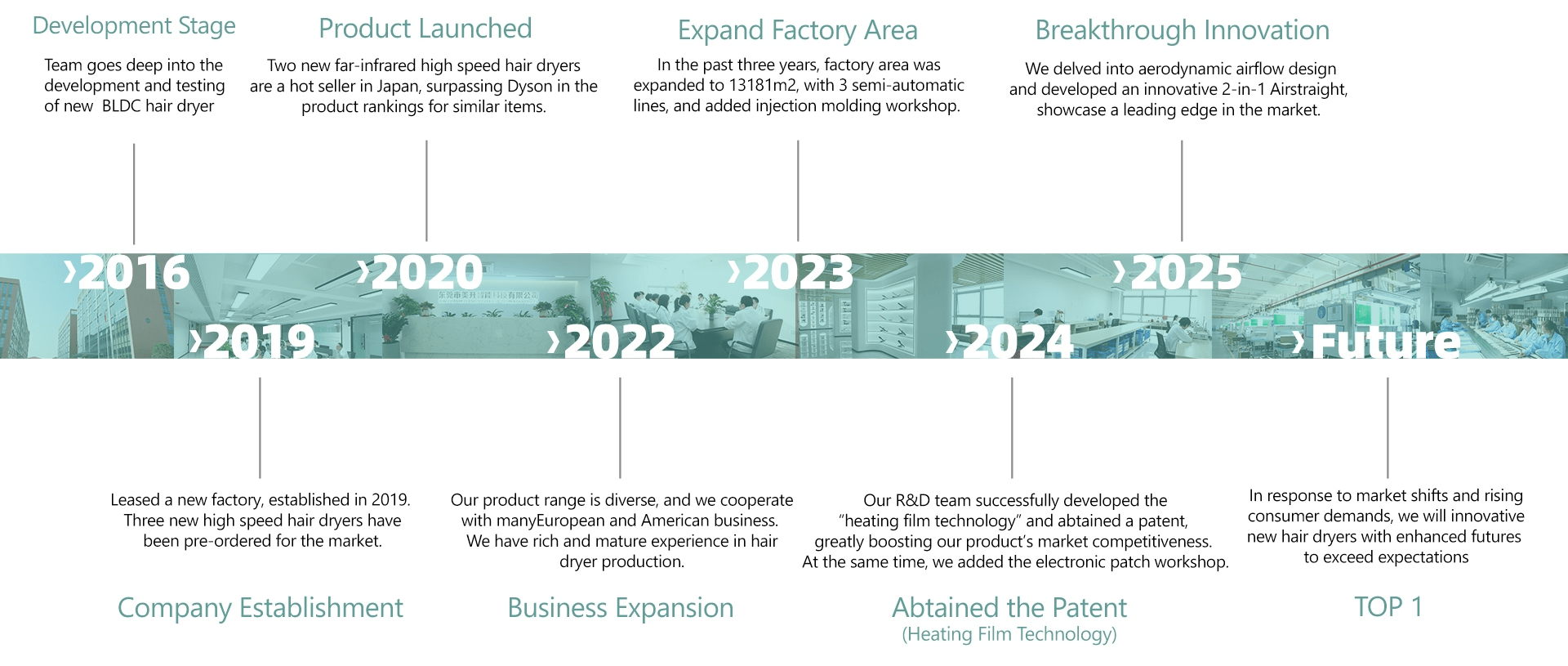

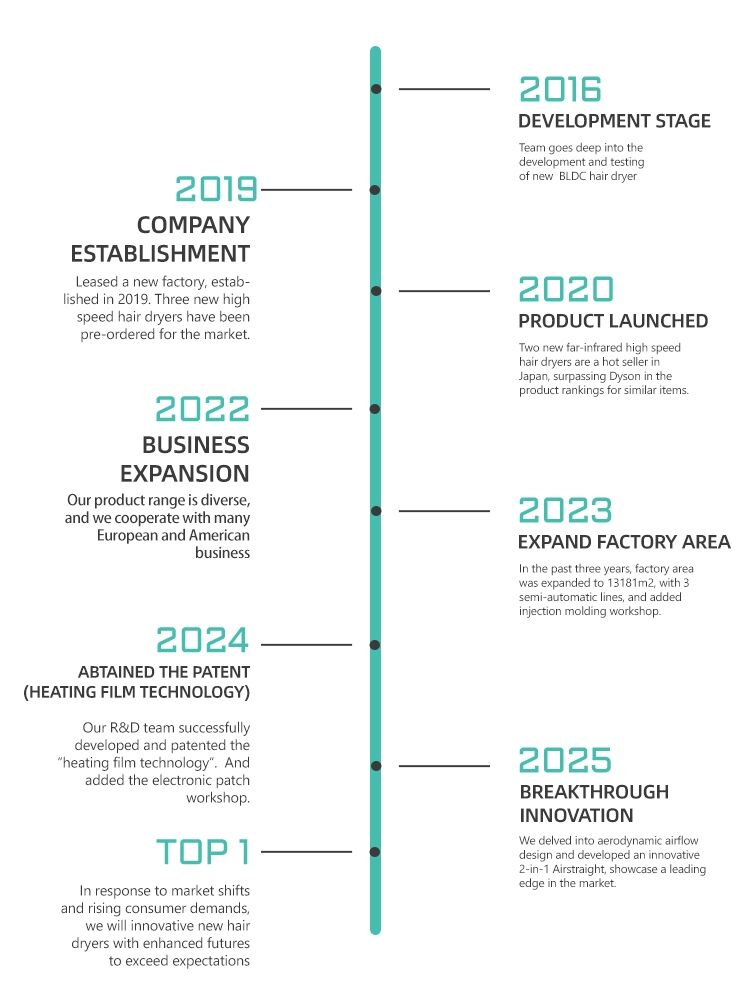

Our company was found in 2019, has more than six years of rich years.

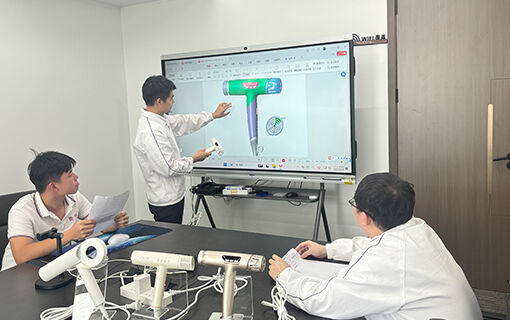

We have 4 R&D centers, Dongguan R&D Center (structural design and testing), Shenzhen R&D Center (software and hardware development), Japan and Korea R&D Centers (advanced materials development).

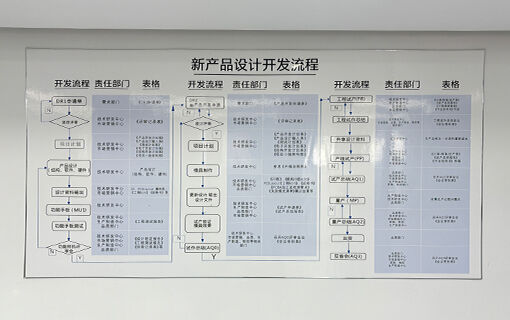

We have established a comprehensive system that integrates in-depth research, agile practices, and continuous integration, ensuring every step from idea to implementation is solid and reliable

Equipped with advanced laboratories(Product Performance Testing Center). Planning to establish a Chemistry lab and an EMC lab within two years.

The factory has introduce 5 semi-automated production lines equipped with advanced equipment, effectively improving production efficiency and quality stability.

We have abtained certifications such as BSCI, ISO9001 Quality Management System, and ISO14001 Enviromental Management System. Additionally, we continuously optimize and improve our quality management processes in accordance with ISO standards.

Panasonic management system is built on a profound business philosophy and systematic management mechanisms. Its core can be summarized as follows: customer-first quality control, inheritance of craftsman spirit and comprehensive quality management system

We provide full-spectrum incoming inspection services to ensure raw materials, components, and outsourced parts meet technical standards and operational requirements.

Finished goods inspection is the last crucial safeguard before product delivery, directly impacting brand reputation and customer inspection. We adhere to a “zero-defect delivery” philosophy, ensuring every product perfectly meets standard requirements.

The company has an efficient and reliable supply chain management system that ensures the stability of raw material supply, reasonable inventory levels, and timely product delivery. Our supply chain management system has been optimized over many years to handle market fluctuations and unexpected events, guaranteeing smooth operation at every stage.

Through systematic and standardized meticulous management, we ensure that every material entering the production line is an optimal condition, laying a solid foundation for the outstanding performance of the final product.

In the fields of precision manufacturing and R&D, accurate and reliable testing is the cornerstone of quality assurance and technological innovation